Drying technology

Download

Gentle drying under vacuum

Among the thermal processes, vacuum drying has proved particularly successful in many industries. The aim of this process is to gently dry a high-quality product mixed with water or solvent without changing the product properties.

When drying under vacuum, the total pressure in the drying oven is lowered so that water or solvents change from the liquid to the vapor phase even at low temperatures.

The drying process is optimized through targeted heat supply and pressure control.

Basically, a vacuum drying system consists of a drying oven with a heating system and a vacuum pumping station tailored to the specific drying process with a corresponding control system.

- Condensation

- Melting

- Sublimation

- Triple point (0.01 °C/6.09 mbar)

Vacuum drying ovens / isolators – products at a glance

The right equipment and systems for drying and process technology: for laboratory (VSD-e) and standard drying processes (VT), for a GMP/FDA-compliant process (VSD) through to the safe drying of HAPI products (VSDI) and for pre-filtration and drying of liquid, toxic products (VSDIN).

VSD

- Vacuum drying oven

- Drying principle:

Vacuum, heat - Materials:

High-quality stainless steels, special materials such as Hastelloy, Inconel, titanium - Surface ground and polished

VSDI

- Vacuum drying oven with isolator

- Drying principle:

Vacuum, heat - Materials:

High-quality stainless steels, special materials such as Hastelloy, Inconel, titanium - Surface ground and polished

Everything from a single source for every customer requirement – our solutions

PINK views customer requirements as a challenge and analyzes them carefully in order to develop optimal products that are superior to conventional standard solutions. PINK offers the entire package from a single source.

Our services at a glance:

- Consulting, planning and project planning

- Design & Development

- Mock-up studies for ergonomic product handling

- Production

- Software development, plant control and visualization

- Documentation, qualification and validation

- Delivery, installation, commissioning, training

- Service and spare parts supply

PINK attaches the utmost importance to the reliability and performance of the systems and the components used. All vacuum systems are helium leak-tested and checked by means of pressure rise measurement. The tests are documented with a test certificate.

PINK – The supplier for your complete solution

As a system supplier, PINK not only manufactures individual dryers in a wide variety of designs, but also supplies complete systems with the entire system peripherals. PINK offers the suitable drying cabinet, depending on customer requirements optionally (in conjunction) with:

- Vacuum pumping systems

- Heating-cooling combinations

- CIP cleaning systems

- Control and visualization

- Remote maintenance facility (VPN)

- 21 CFR Part 11

- DQ (Design Qualification)

- IQ (Installation Qualification)

- OQ (Operational Qualification)

- GAMP 5

- Automated feeding and integration into existing production lines

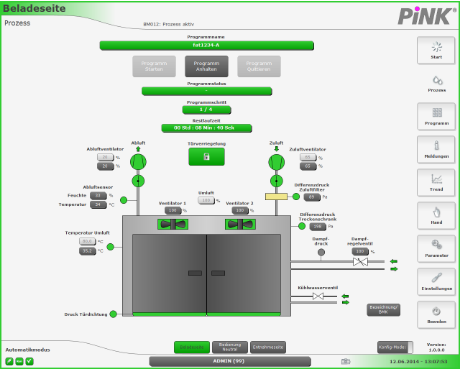

User-friendly touch panel

It is operated via a user-friendly touch panel with clear and simple menu navigation, developed by PINK

Vacuum drying oven type VSD

Vacuum drying oven type VSD in double chamber design with complete peripherals – everything from a single source

Contact us and let us work together to develop solutions that meet your requirements. We look forward to hearing from you and helping you further.