Plasma technology

Download

Systems for surface treatment with low-pressure plasma

Efficient processes for the best results

Activate in plasma

Low-pressure plasma technology can be used to activate or chemically modify polymer surfaces in a simple and efficient way during plasma activation. Activation enables subsequent processes such as painting, bonding, printing and potting – without thermal stress on the material (cold plasma) and without aggressive primers.

Cleaning in plasma

The cleaning of surfaces plays an important role in industrial practice, e.g. in increasing the adhesive strength of coatings. Plasma cleaning leaves surfaces completely free of organic contaminants. As this is a dry chemical process at room temperature, the cleaned parts can be processed immediately.

Etching in plasma

Plasma etching (dry etching) is used for the removal (“descum”, “desmear”, “back etch” etc.) of production auxiliaries such as photoresist and sacrificial layers. Practically any organic material can be processed with plasma etching. Thanks to the pronounced mobility of the plasma, even the finest structures can be reached. Another application for plasma technology is the desmearing or etching back of mechanically drilled circuit boards.

Plasma coating

In plasma coating, materials or workpieces are given thin functional layers by polymerizing and depositing suitable precursor compounds on surfaces in the plasma state. This enables a defined coating effect to be achieved on a wide variety of materials. The plasma polymerization coating process is also known as PECVD (plasma enhanced chemical vapour deposition).

The gentle power of the fourth state of matter

Matter changes its appearance at certain temperatures. In general, the aggregate states of solid, liquid and gaseous matter are known, but there is another state of matter – plasma. A plasma is the ionized form of a gas and is also referred to as the “fourth state of matter”. The difference between the neutral gas and the plasma is the significantly higher electrical conductivity and chemical reactivity.

Low-pressure plasma - energy without heat

At atmospheric pressure, a plasma is very hot. Examples of this are flames and arc discharges. If the pressure is reduced to e.g. 100 Pa, a plasma can be generated at lower temperatures. The result is a so-called cold plasma or, more precisely, a non-thermal plasma.

During treatment with low-pressure plasma, the material to be treated is only heated insignificantly as the gas has a very low temperature. However, the energy of the electrons corresponds to a temperature of several 1,000 K. This advantage enables the treatment of plastics or other temperature-sensitive materials, among other things.

The principle of low-pressure plasma

Efficient processes for the best results

- Wide range of applications

- Neutral plasmas

- Reactive plasmas

- Environmentally friendly and efficient

- Exemplary low-pressure plasma treatment effects

Low-pressure plasma systems – products at a glance

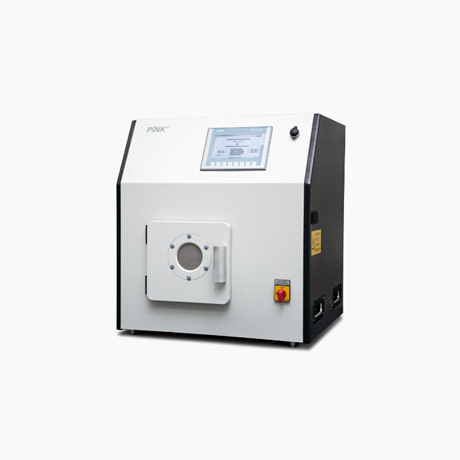

The product range of standard systems extends from the compact V6-G low-pressure plasma table-top unit, which is ideal for plasma applications in small series production as well as for test series in research and development, to the floor-standing systems, which can be equipped with different plasma generation frequencies and outputs and can therefore be used variably for a wide range of plasma processes.

Contact us and let us work together to develop solutions that meet your requirements. We look forward to hearing from you and helping you further.

Application examples – Application Notes

Medical technology: Syringe needles

The bonding of a steel needle in the hubs for syringes must have a high tensile strength, otherwise there is a risk of the needle coming loose during use. To achieve the desired adhesive strength, the polyethylene hubs are pre-treated in plasma (activated). As the plasma is gaseous, the inside of the hubs in particular can also be treated without any problems.

Chip card production

The adhesion of the modules in chip cards is of decisive importance for the quality and service life of the cards. If it is too low, the module can detach from the chip card, e.g. in the event of heavy bending stress, and render the card unusable. To prevent this and to achieve optimum adhesion of the hot-melt bonding, the modules are activated in the plasma before bonding.

Dental medical technology

The quality requirements in terms of function and service life are extremely high in medical technology. The repeated sterilization processes have a particularly negative effect on the materials. Hot steam sterilization in particular leads to degradation of the polymer surfaces. Adhesive bonds and paintwork are particularly attacked and lose their adhesive strength after repeated hot steam treatment, so that important functionalities are lost. The aim of plasma treatment is to significantly increase the adhesion between the polymer workpiece and the adhesive or lacquer.

Borehole cleaning

Structured films are used in the manufacture of cartridges for inkjet printers, for example. The holes required for this in the film – e.g. Kapton™ (polyimide) – are created using a laser. This results in ashing products, which are deposited as a black coating around the holes and have a disruptive effect on the subsequent processing steps. The aim of plasma treatment is to remove this coating.

Automotive electrics: Ignition coil production

The quality requirements in terms of function and service life are very high in the automotive sector. One example is ignition coils, which are used (in cuboid or rod form) to operate gasoline engines. To guarantee a long service life, the ignition coil must not come into contact with moisture, as this could lead to a short circuit.

Read more: Automotive electrics: Ignition coil production, PDF 130 KB

Leadframe editing

The cleanliness of the surface is crucial for sufficient adhesion of bonding wires to lead frames. Optimum adhesion properties and the best quality of bonded joints can only be achieved if the bond pads are guaranteed to be very clean in terms of organic residues. This purity can be achieved by treatment in a low-pressure plasma. Due to the high mobility of the plasma, lead frames in magazines are completely cleaned.

Plasma cleaning of blinker bulbs

Even today, blinker bulbs are still used in the automotive industry. These are often painted, as the lenses of the indicators are often colorless for economic and visual reasons. The bulbs are painted in an immersion process after production. The service life of the paint depends on the adhesion of the paint to the substrate. The contamination is only a few μg/cm2, but it significantly reduces adhesion. The paint sometimes flakes off after just a few hours of continuous use.

Electrical engineering: Quality capacitors

The capacitors described here consist of a polymer film metallized (e.g. with aluminium or zinc), which is wound up and pressed into its final shape. Subsequently, wires are fixed to the end face by melting aluminum powder and the capacitor is sealed with a plastic cap. The adhesion of the aluminum powder is impaired by impurities. By using a plasma process, these are removed and the adhesion problem is eliminated.

Read more: Electrical engineering: Quality capacitors, PDF 99 KB

Stripping photoresist

The removal of photoresist layers is a frequently occurring process step in the manufacture of microelectronic components. Isotropic stripping processes enable the removal of organic layers without causing so-called plasma damage. PINK has extensive experience in the low-pressure plasma surface treatment sector and also offers customized paint removal systems.

Hole etching in printed circuit board foils

Films are used today in a wide variety of technical areas. One interesting field of application is the production of printed circuit boards using high-quality materials. The foils are first structured using an embossing technique and then metallized. Holes must be made in the foils to enable through-hole plating.

Read more: Hole etching in printed circuit board foils, PDF 88 KB