Induction vacuum soldering system

The compact VADU 100-I induction vacuum soldering system produces void-free solder joints and is primarily designed for flux-free soldering such as preform soldering. It is equipped with separate process zones for soldering and cooling.

The soldering zone is divided into two separately controllable induction zones. Thanks to its small dimensions and high level of user-friendliness, the batch system is particularly suitable for the production of small product series and for laboratory applications in the development sector.

VADU 100-I vacuum soldering system

Data sheet

| System type | Batch system |

| Number of vacuum chambers | 1 chamber with 2 separate process zones |

| Usable area (W x D) | 168 x 280 mm (e.g. 2 cards á 4 x 6") |

| Sluice height | max. 50 mm |

| Vacuum (standard) | ≤ 2 mbar |

| System dimensions (W x D x H) | 1,330 x 1,380 x 1,200 mm |

| Dimensions of the pumping station | Integrated |

| Weight | 600 kg |

| Electrical connection | 3 x 400 V, 50/60 Hz |

| Connected load | 5 kVA |

| SMEMA interface | - |

Options

| Traceability (traceability) | |

| Handling / transfer systems | |

| Integrated MES interfaces (e.g. SECS/GEM) | |

| Cooling unit | |

| Pin cooling to avoid blowholes during cooling |

System properties

- Blowhole-free soldered joints

- Two separately controllable induction heating zones

- Individual soldering profiles

- Heat generation directly in the soldering material

- Process temperatures up to 500 °C

- Separate soldering and cooling zones

- Inert protective gas atmosphere

- Residual oxygen content < 5 ppm

- Formic acid process for flux-free soldering

- Soldering with preforms and / or pastes

- Short cycle times

- Condensate separation

- Reproducibility of the soldering results

- Continuous process control

- Ethernet interface

- Remote maintenance (VPN)

- Low energy and media consumption

Further vacuum soldering systems

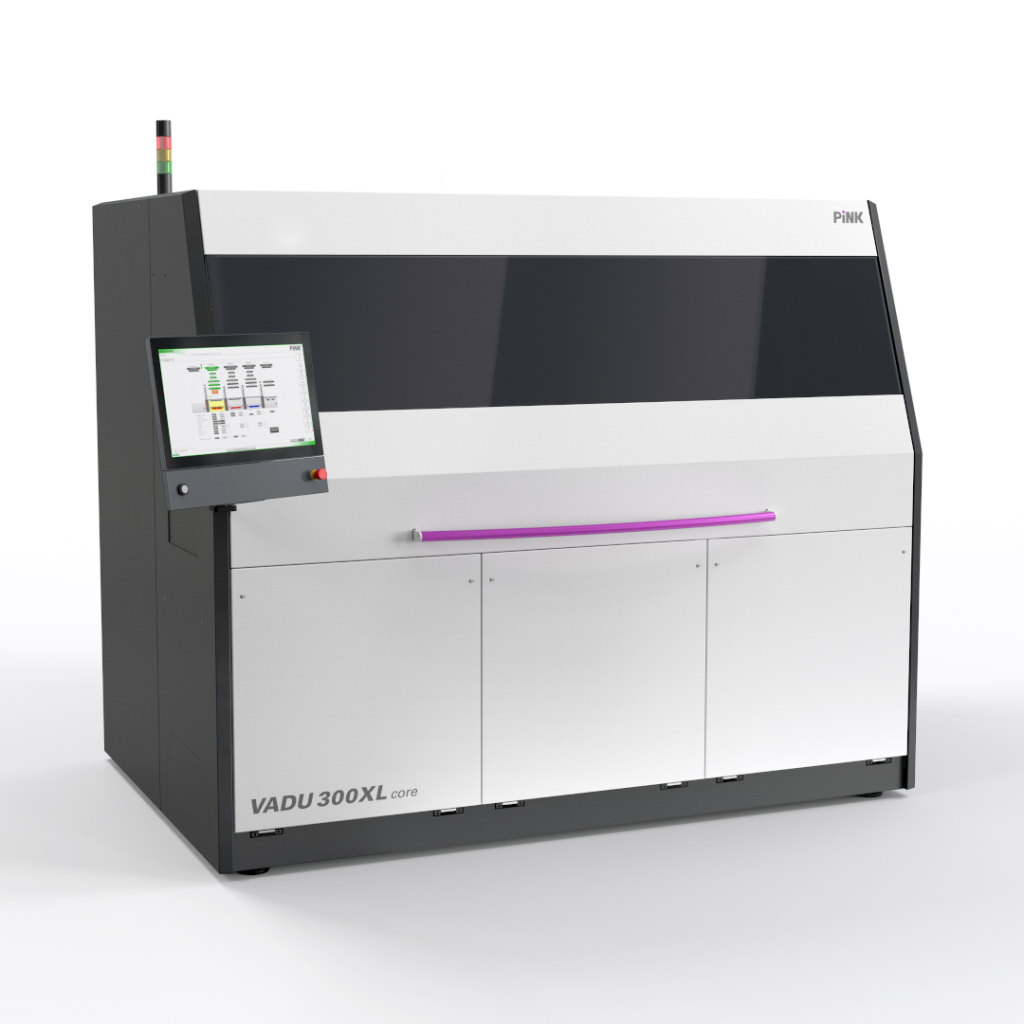

VADU 200XL-W

Batch system

2 vacuum chambers

Throughfeed height max. 100 mm

Size: 1,200 x 1,890 x 1,680 mm

You need more

information?

Contact us and let us work together to develop solutions that meet your requirements. We look forward to hearing from you and helping you further.