The flexible sintering system SIN 200+ modular

For extraordinarily reliable, highly thermally conductive bonds

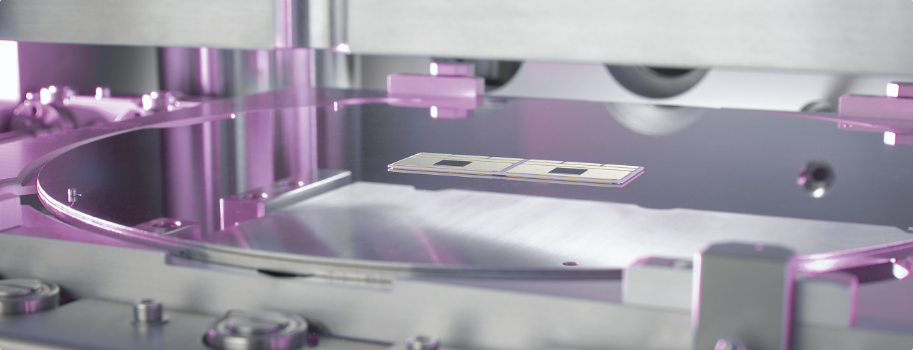

The patented sintering system SIN 200+ modular is a highly flexible system, which is suitable for various production demands from laboratory up to series production, as the system is modular designed and can be operated as a batch system or an automated inline system with different preheating and/or cooling modules.

The substrate temperature, the atmospheric pressure and gas composition during the entire heating, sintering and cooling procedure within the vacuum chamber/s is exactly controllable at any time. In combination with the dynamic adaptability of the pressing force the system provides a wide array of novel process and production possibilities.

Options

- Connection of pre-heating and/or cooling modules

- Customer specific automation by addition of handling/transfer systems

- Workpiece heating optional from top or bottom side

- Other dimensions of the process area on request

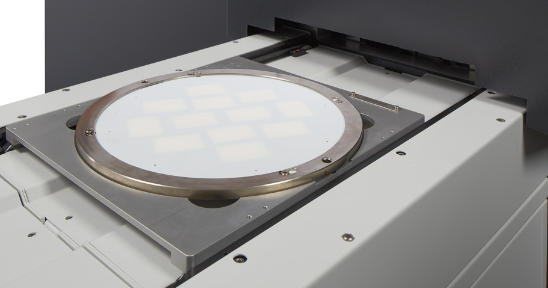

Inline system SIN 200+ modular

Automated inline system SIN 200+ modular with preheating, sintering and cooling module. Fully automated handling system for loading and unloading on PINK carriers as well as with transfer system with underfloor return and lifting units.

System features

- Modular design with flexible expandability

- Pressing force: up to 2,000 kN (200 t)

- Dynamic controlled and monitored pressure ramps

- Press tool exchangeable (e.g. for customer specific tool)

- Programmable, controlled and monitored temperature profiles

- Temperature range: up to 350 °C

- Integrated heating technology

- Hermetically sealed process chambers

- Atmospheric pressure range: 1-1,200 mbar

- Exact control of inherent gas atmosphere (N2, N2/O2, N2/H2, HCOOH)

- Process area: ≤ 280 mm diameter

- Manual or automatic loading and unloading

- Patented system

- Constant process control and traceability

- Easy operation by touch panel

- Integrated interface to MES (e.g. SECS/GEM)