Vacuum soldering system VADU 100-I

For highest precision in temperature control

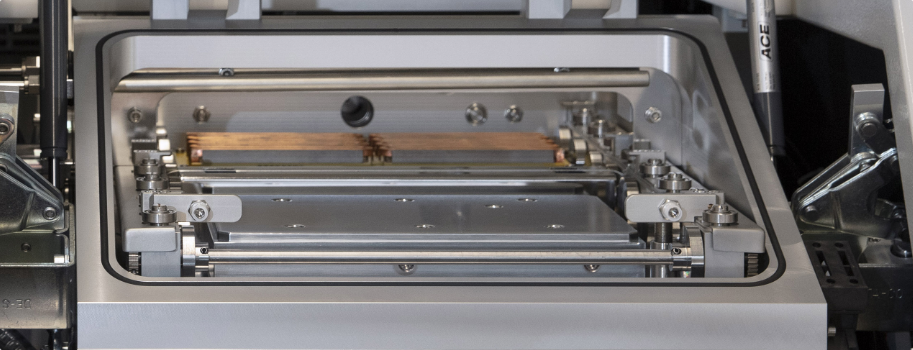

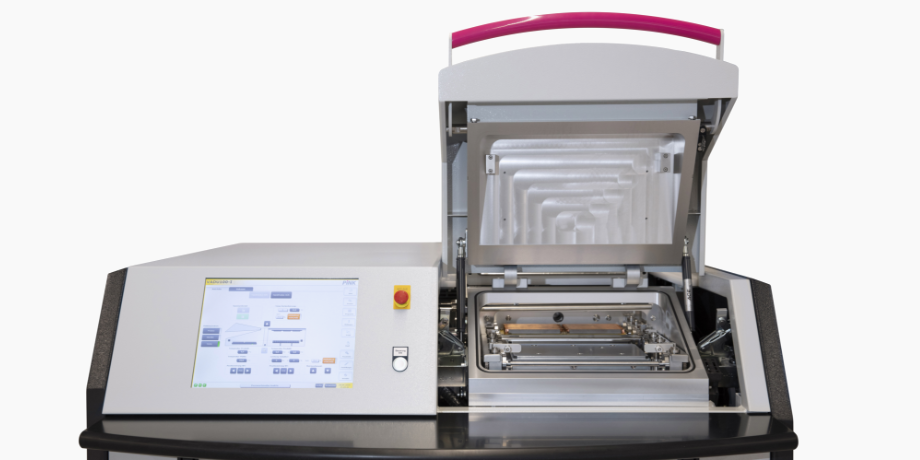

The compact soldering system VADU 100-I operates primarily with preforms and generates void-free solder connections. It is equipped with separate process zones for soldering and cooling. The soldering area is divided in two controllable inductive heating zones.

Due to its small dimensions and the easy operation, the batch system is very suitable for production of small series and in laboratories for research applications.

Vacuum Soldering System VADU 100-I

With its vacuum-supported soldering process and the newly designed induction heating the system VADU 100-I

stands for high-quality void-free soldering results, even in small series production

Data sheet

| Type of system | Batch system |

| Number of vacuum chambers | 1 chamber with 2 separate process zones |

| Process area (W x D) | 168 x 280 mm (e.g. 2 Cards à 4 x 6") |

| Clearance height | max. 50 mm |

| Vacuum (standard) | ≤ 2 mbar |

| Dimensions of the system (W x D x H) | 1,330 x 1,380 x 1,200 mm |

| Dimensions of pumping unit | Integrated |

| Weight | 600 kg |

| Power supply | 3 x 400 V, 50/60 Hz |

| Power input | 5 kVA |

| SMEMA interface | – |

Options

| Traceability |  |

| Handling / transfer systems |  |

| Integrated MES interfaces (e.g. SECS/GEM) |  |

| Cooling system |  |

| Selective pin-cooling for the prevention of voids during cooling |  |

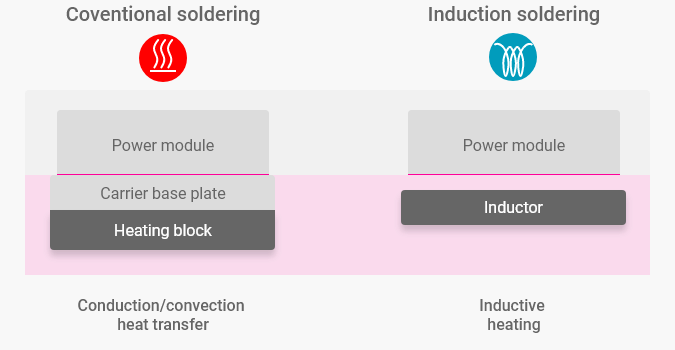

Conventional vs. Induction Soldering

System features

- Void-free solder connections

- Two separate controllable inductive heating zones

- Individual soldering profiles

- Heat generation directly in the product

- Soldering temperatures up to 500 °C

- Controlled temperature gradients

- Separate soldering and cooling zone

- Inert gas atmosphere

- Residual oxygen content < 5 ppm

- Flux-free soldering with formic acid

- Soldering with preforms and / or pastes

- Short cycle times

- Flux management

- Reproducibility of the soldering results

- Permanent process control

- Ethernet interface

- Remote maintenance (VPN)

Compare systems

|

Type |

VADU 100 | VADU 200XL | VADU 300XL | VADU 400XL |

| Type of system | Batch system | Batch or Inline system | Inline system | Inline system |

| Number of vacuum chambers | 1 chamber with 2 separate process zones |

2 chambers | 3 chambers | 4 chambers |

| Process area (W x D) [mm] |

168 x 280 | 410 x 280 | 410 x 280 | 410 x 280 |

| Clearance height [mm] |

max. 50 | max. 100 | max. 100 | max. 100 |

| Vacuum (standard) [mbar] |

≤ 2 | ≤ 2 | ≤ 2 | ≤ 2 |

| Dimensions of the system (W x D x H) [mm] |

1,070 x 1,130 x 1,150 | 1,758 x 1,911 x 2,381 | 2,436 x 1,911 x 2,381 | 3,114 x 1,911 x 2,381 |

| Dimensions of pumping unit [mm] |

Integrated | 1,027 x 762 x 1,376 | 1,027 x 762 x 1,996 | 1,027 x 1,452 x 1,376 |

| Weight [kg] |

500 | 1,500 (without pumping unit) |

2,000 (without pumping unit) |

2,600 (without pumping unit) |

| Power supply | 3 x 400 V, 50/60 Hz | 3 x 400 V, 50/60 Hz | 3 x 400 V, 50/60 Hz | 3 x 400 V, 50/60 Hz |

| Power input [kVA] |

5 | 19 | 27 | 35 |

| SMEMA interface | – |  |

|

|

|

Options |

||||

| Handling / transfer systems |

|

|

|

|

| Soldering temperatures up to 500 °C |  |

|

|

|

| Induction heating |  |

- | - | - |

| Integrated MES interfaces (e.g. SECS/GEM) |  |

|

|

|