Coating with low-pressure plasma

Functional coating of surfaces

A variety of coating options for many different materials

Low-pressure plasma technology is a process by which special functional groups can be deposited on surfaces. In this way, a defined coating effect can be achieved on many different materials.

Such plasma polymerization – so-called PECVD – is a relatively new coating technique, especially suitable for coating of plastics because of the low thermal impact on the substrate. However, it can also be used on an abundance of other materials such as metals, glass, ceramics, semiconductors and textiles.

Areas of application

- Automotive and automotive component industry

- Medical technology

- Sealing technology

- R & D

- Packaging industry

The wide variety of coating properties obtainable due to the many variable process parameters is particularly relevant for industrial coating processes.

For instance, plasma coats can be a primer for subsequent processes. At the same time, such primer coats also can be used as corrosion protection.

Advantages of plasma coating

- Wide variety of options regarding coat properties

- Low thermal stress, therefore also suitable for temperature-sensitive plastics

- High thermal and chemical stability of the coats

Resistant – even with extremely thin coats

In general, plasma-polymerized coats are highly cross-linked three-dimensionally. Therefore, they are thermally and chemically very stable.

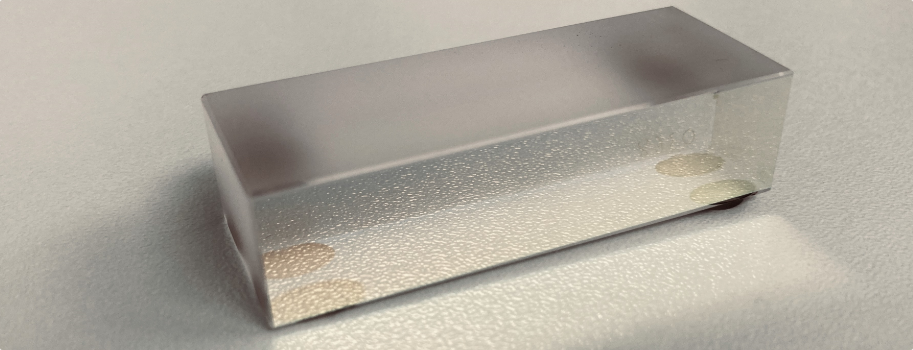

Plasma coating

The runout performance of hybrid roller bearings (steel ring with ceramic rollers) can be improved by plasma coating

Foto: Cerobear GmbH

Coating options

- Hydrophobic coats

- Hydrophilic coats

- Diffusion-proof coats

- Biocompatible coats

- Primer coats

- Anti-icing coats